THE MAGAZINE FOR COMPUTER APPLICATIONS Circuit Cellar Online offers articles illustrating creative solutions and unique applications through complete projects, practical tutorials, and useful design techniques. |

|

| March 2000 |

|

|

|

|

A Guide to online information about: Metglas® by With today's obsession with smaller, faster, lower power, sometimes we need every little bit of help we can get. One area of power supply design and shielding that has not made it to the main stream until now is the use of Amorphous Metals. The most sysinct explanation of exactly what is meant by Amorphous Metals comes from NASA's Microgravity research program office in the paper:"This material offers the potential of reducing the core losses of motors and transformers by more than 70%" - Applications of Low Loss Amorphous Metals in Motors and Transformers by L.A. Johnson, E.P. Cornell, D.J. Baiely, S.M. Hegyi; 81 TD 641-0. A paper recommended and approved by the IEEE Transformers Committee of the IEEE Power Engineering Society for presentation at the IEEE PES 1981 Transmission and Distribution Conference and Exposition. - Containerless Production of Bulk Metallic Glasses (74-49) - "When a metal or alloy solidifies, it usually divides into many small crystals. The atoms in each of these crystals are arranged in a periodic fashion known as a crystal lattice. Certain metal alloys, however, can be cooled so fast that the atoms do not have time to arrange themselves in a regular fashion but are instead arranged in a more or less random fashion like the atoms in ordinary glass. Such disordered materials are termed amorphous and have very different properties from the same material in a crystalline state. Present techniques for fast cooling of metals on Earth require that the metal be in very thin ribbon form so that heat can be extracted quickly." Gravity is such an accepted part of our lives we rarely think about it even though it affects everything we do. Any time we drop or throw something and watch it fall to the ground, we see gravity in action. Although gravity is a universal force, there are times when it is not desirable to conduct scientific research under its full influence. In these cases, scientists perform their experiments in microgravity—a condition in which the effects of gravity are greatly reduced, sometimes described as "weightlessness." A microgravity

environment gives researchers a unique

opportunity to study the fundamental states of

matter (solids, liquids, and gases) and the

forces that affect them. In microgravity,

researchers can isolate and study the influence

of gravity on physical processes, as well as

phenomena that are normally masked by gravity

and thus difficult, if not impossible, to study

on Earth. CUT RESISTANT GLOVES MUST BE WORN AT ALL TIMES WHEN HANDLING METGLAS DT CORES. The METGLAS transformer core alloy utilized in these cores is cast in extremely thin and sharp ribbons (25 to 50 µm). Finger marks may cause core corrosion. Please wear appropriate safety

equipment when handling METGLAS DT

cores.

Amorphous Metals is the world's leading producer of amorphous metal ribbon and components used in the production of electrical distribution transformers, high frequency switching power supplies, anti-theft tags, brazing alloys, and solder. Based on technology developed at AlliedSignal's research facilities in Morristown, NJ, the unit began developing amorphous metals in 1970. Amorphous Metals, also known as metallic glass alloys, differ from traditional metals in that they have a non-crystalline structure and possess unique physical and magnetic properties that combine strength and hardness with flexibility and toughness. Key Products: METGLAS®; Amorphous Metal; Glassy Metal; Metallic Glass; Transformer Core Alloys; Distribution Transformer Cores; METGLAS® High Frequency Cores including the Magnaperm®, Microlite®, and Powerlite® product lines; METGLAS® brazing foil; and Specialty Products. High Frequency Cores —METGLAS® low profile amorphous metal cores improve switched mode power supplies (SMPS) performance and reduce size and weight. For SMPS/UPS design, high-frequency electronic cores made with METGLAS® amorphous metal alloy consistently out-perform conventional silicon-steel or ferrite cores. The amorphous structure of the METGLAS® alloy provides lower coercivity, making it the easiest of all ferromagnetic materials to magnetize. This allows faster switching in cores for higher frequency operation. All METGLAS® high-frequency cores experience up to 70% lower losses than cores made of any other material. In addition, amorphous cores have higher saturation inductions than conventional cores, requiring less material for the same applications. This is especially important in circuit design, where optimizing space is always a prime concern. MICROLITE® Toroidal Cores are manufactured with METGLAS® Amorphous Alloy-SA1 ribbon. "Their unique combination of high saturation flux density and low loss make them the first choice for all energy storage applications, while their distributed gap format renders a distinct RFI advantage compared to conventional air gapped cores, enabling the designer to achieve both size and system cost reduction." METGLAS® Pulse Power Cores - for high voltage, high power application requiring short, narrow pulses at high rep rate. SATURABLE REACTORS Saturable reactors utilize the large change between unsaturated and saturated permeabilities of their cores to delay current for a preset period of time. Similarly, once saturated in the forward direction, they act as a diode temporarily blocking current in the reverse direction. A Mag Amp is a good example of how to use a Saturable Reactor. MAGNETIC SWITCH PROTECTION (MSP) MSP devices made with METGLAS® cores dramatically enhanced the reliability and overall lifetime of pulse power systems. By using a saturable reactor in series with either a semiconductor or thyratron switch, the circuit designer can reduce losses in the switch and extend its life. The saturable reactor is designed to hold-off current until the switch becomes fully conductive (see figure, above). This delay reduces the overlap between current and voltage in the switch, thereby reducing power absorber in the switch. MSP also offers other advantages. Higher di/dt's to the load are safely achieved by waiting for full conductivity in semiconductor switches. The diode-like characteristic of a saturated reactor provides time for switch recovery.

MAGNETIC PULSE COMPRESSION (MPC) Magnetic pulse compression utilizes reactors in conjunction with capacitors to shape input pulses into narrow output pulses of much higher current (see above figure). MPC, therefore, allows you to use less expensive input switches with lower current ratings. MPC can also extend the lifetime of the input switch. Advanced MPC devices (capable of generating power levels of multi-terawatts in tens of nanoseconds) have been realized utilizing METGLAS® cores. "INDUCTION LINEAR ACCELERATORS FOR PHYSICS DIAGNOSTICS" shows a real world example. Lawrence Livermore National Laboratory has developed a non-linear magnetic core model for circuit design and analysis of the Heavy Ion Fusion Projects MOSFET (metal oxide semiconductor field effect transistor) switched modulator...the first stage of development of a compact, modulator module for driving pulsed plasma loads. The module is capable of generating 800 V, 150 ns pulses at a pulse repetition frequency (prf) of 10 kHz continuous operation. Voltages as high as 50 kV, with pulse widths on the order of 200 ns and prfs of >50 kHz, can be achieved by stacking additional modules. Magnetic Materials - For complete listing of METGLAS® amorphous alloy developed by AlliedSignal. Advanced Electrical Transformer Cores & Alloys - for utility transmission and distribution (T&D) systems and commercial/industrial applications reduce operating costs and increase energy efficiency. More than ever, electric utilities and industries today are searching for technologies to reduce their operating costs and improve energy savings throughout their systems. New transmission and distribution (T&D) technologies are now available to help utilities meet these goals. With a new generation of Metglas® amorphous metal distribution transformers (AMDTs)—with up to 80% lower core loss than conventional transformers—AlliedSignal is helping utilities worldwide achieve their efficiency objectives. When you consider that 10% of all electricity generated by utilities is lost in the transmission and distribution process, the potential savings through reductions in core loss can be significant. Ultra-efficient transformer cores made with AlliedSignal's METGLAS® amorphous metal alloy make lower core losses possible. Amorphous metal distribution transformers are key to improving utility economics and enhancing energy conservation efforts worldwide.

Brazing/Soldering - for reliable metal

joining, METGLAS® foils and preforms offer

consistent strength, flexibility, and

temperature resistance. Soldering alloys enable

uniform and precise joints. National-Arnold Magnetics is now a world-class producer of Amorphous C-Core Products. Higher power to weight ratios are achieved as a result of the magnetic materials utilized in the design of the LIGHT ENGINE. The

Naval Research Laboratory's (NRL)Materials

Physics Branch (Code 6340) Non-Linear

Physics Group is studying Magneto-elastic

spatial/temporal chaos in Metglas®

films. Also, don't miss their

'Chaos' circuits.

Magnetic Core Selection for Transformers and Inductors, Second Edition 630 Pages, 165 Figures and over 50 Tables. Author: Colonel Wm. T. McLyman Core data to include the latest

magnetic materials, such as Kool Mu, Metglas,

and Ferrite materials. TITLE: ABSTRACT/BENEFITS:

Pulser Technologies Defense Sciences Engineering Division has unique facilities and capabilities in addressing high voltage and high current fast rise time pulser design and system integration. These pulsers are typically used in charge deposition, imaging, and radar systems at Lawrence Livermore National Laboratory. Design work involving Avalanche Transistor Pulsers was presented at the 1994 Power Modulator Symposium and demonstrated the reliability of such designs in a small package. The Fast Pulse

Development Team (FPDT), located at the

Lawrence

Livermore National Laboratory (LLNL),

performs work in designing, testing, and

evaluating systems in the area of small scale

High Speed Pulsed Power, and High Speed Data

Acquisition and Diagnostics. FPDT performs DOE

and Commercial research and design that is in

the national interest. Theft Prevention - Proprietary METGLAS strips are used in high-accuracy electronic article surveillance (EAS) systems used by retailers for better inventory control and to detect shoplifters. What

is Tagging Systems? Tagging Systems RF

Radio frequency systems EM Magnetic systems

Loop system Acousto-magnetic systems Systems

divide roughly into two types. RF (Radio

frequency) and Magnetic. ("Coming Soon Online" according to the Amorphous Metals site.) MAGNETIC AMPLIFIER OUTPUT REGULATORS Metglas Products has produced a detailed 24-page application guide for the design of high-frequency mag amp regulators using amorphous alloy. This guide provides a complete description of the mag amp design process, a core specification guide, and reference to the key technical literature on mag amp regulators. Mag amp (magnetic amplifier) output regulators are a popular means of regulating more than one output of a switching power supply. They offer precise regulation of each independent output and are efficient, simple, and reliable. Mag amps are especially suitable for outputs with currents of 1A to several tens of amperes, although they are also used at lower currents where tight regulation and efficiency are essential. The advent of Metglas® Amorphous Alloy 2714A made possible the design of mag amps that can operate at higher frequencies than previously possible. Cores made from this alloy exhibit (1) a high squareness ratio, giving rise to low saturated permeability; (2) low coercive force, indicating a small reset current; and (3) low core loss, resulting in a smaller temperature rise. This combination of magnetic properties enables Metglas® electronic cores to provide superior precision and efficiency in output regulation. Here are the first couple of pages: DESIGN OF HIGH-FREQUENCY MAG AMP

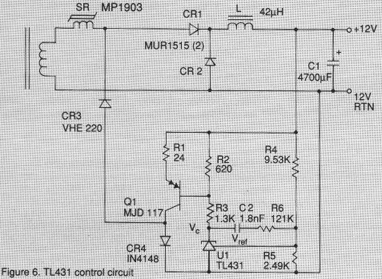

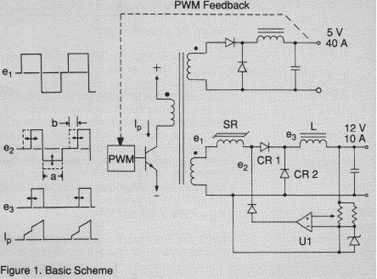

OUTPUT REGULATORS Mag amp (magnetic amplifier) output regulators became quite popular over the past few years as a way of regulating more than one output of a switching power supply. They offer extremely precise regulation of each independent output, and are efficient, simple and very reliable. Mag amps are particularly well suited for outputs with currents of 1 amp to several tens of amps, although they are also used at lower current where tight regulation and efficiency are extremely important. The advent of Metglas® amorphous alloy 2714A made possible the design of mag amps that can operate at higher frequencies than previously possible. Cores made from this alloy exhibit: (1) a high squareness ratio, giving rise to low saturated permeability; (2) low coercive force, indicating a small reset current and (3) low core loss, resulting in a smaller temperature rise. This combination of outstanding magnetic properties enables Metglas® Electronic Cores to provide unparalleled precision and efficiency in output regulation. Although linear regulators and independent switched-mode regulators are also used for regulating outputs, they become somewhat limited at higher frequencies and output currents. Linear regulators are limited by their inefficiencies in handling output currents that exceed one or two amperes. At higher currents, heat sinking schemes are required, which increases the size and cost of the power supply. Independent switched-mode sub-regulators avoid this inefficiency, but usually require a more complex circuitry which is typically more expensive and less reliable than the mag amp approach. This application note describes the operation of modern mag amp regulators and guides the reader through the design of the saturable reactor and the control circuitry. Appendix A contains a detailed design example of a simple, low-cost mag amp regulator. Appendix B gives the criterion for choosing the output filter inductor, and Appendix C addresses the design of a control circuit using current-mode feedback. MAG AMP REGULATOR OPERATION A mag amp controls an output of a switched-mode power supply by modifying the width of the pulse, which appears at the appropriate secondary of the power transformer before the pulse is "averaged" by the output filter. It does this by delaying the leading edge of the pulse in the same manner as a series switch, which is open during the first portion of the pulse and then closed for the rest of the pulse. The switching function is performed by a saturable reactor—an inductor wound on a magnetic core having a very square B-H loop. The function of the mag amp is illustrated in Figure 1. In this case, a 12-V, 10-A

tightly-regulated output accompanies a 5-V,

40-A main output on a forward converter type of

switched-mode converter. The error amplifier U1

controls the reset of the saturable reactor

between power pulses, and this reset determines

the delay which occurs at the leading edge of

the following power pulse. Waveform

e2 shows the voltage at the output

side of the saturable reactor SR, with the

voltage during interval (a) being controlled by

the amplifier. The delay time, interval (b),

ends when its volt-second product equals the

volt-second product applied to the reactor

during interval (a). The resulting waveform at

the input of the averaging inductor The primary current, L, steps up at the time the core saturates, as a result of the output current commutating from diode CR2 to diode CR1. To visualize the operation of the

feedback loop, assume the output voltage is too

high. This causes the positive (+) input of the

amplifier to rise, driving the output of the

amplifier in the positive direction. This

raises the clamping level

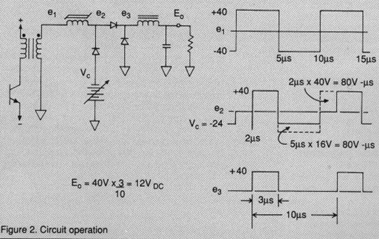

Figure 2 illustrates the operation of the saturable reactor in detail. Assume that a 12-V output is desired from a secondary circuit which would normally produce 20 V. To produce the 20-V output, the waveform at e1 is a square wave with a peak voltage of 40 V and a duty ratio of 0.5. Thus, if the saturable reactor were replaced with a jumper wire the output would be 20 V. This is a result of the output filter averaging the voltage at its input. With the saturable reactor installed and a clamp voltage (Vc) set at -24 V, the applied reset will be 16 V x 5 us, or 80 volt-microseconds. When the positive pulse is applied to the input of the saturable reactor, the reactor behaves as an open switch until the reset volt-microsecond product expires. Since the applied voltage is 40 V, the delay is 2 microseconds. The pulse applied at the input of the filter (e3) is a 40 V pulse with a duration of 5 - 2 = 3 microseconds. The output voltage is the average of this waveform, namely (40 V x 3 us) / (10 us) =12 V. In addition to regulating, mag amps are often required to provide current limiting of the individual output. In fact, the requirement for the mag amp reactor is the same for current limiting as it is for regulating down to low values of output current, where the output choke (or output inductor) current is discontinuous. In these cases the saturable reactor must withstand the entire volt-second product of the input waveform. Thus, there are two categories of application: 1) regulation only, and 2) shutdown. "Regulation only" means that the minimum output current for good regulation is high enough to assure continuous choke current, and independent current limiting of the mag amp output is not required.

Magnetostrictive Transducers, Actuators, and Sensors are one application of Metglas®. Magnetostrictive materials transduce or convert magnetic energy to mechanical energy and vice versa. As a magnetostrictive material is magnetized, it strains. That is, it exhibits a change in length per unit length. Conversely, if an external force produces a strain in a magnetostrictive material, the material's magnetic state will change. This bi-directional coupling between the magnetic and mechanical states of a magnetostrictive material provides a transduction capability that is used for both actuation and sensing devices. Magnetostriction is an inherent material property that will not degrade with time. With the discovery of "giant"

magnetostrictive alloys in the 1970s (materials

capable of over 1000 m L/L) there is a renewed

interest magnetostrictive transducer

technologies. Many uses for magnetostrictive

actuators, sensors, and dampers have surfaced

in the last two decades as more reliable and

larger strain and force giant magnetostrictive

materials, such as Terfenol-D and

Metglas®, have become commercially

available (in the mid to late 1980's). Current

applications for magnetostrictive devices

include ultrasonic cleaners, high force linear

motors, positioners for adaptive optics, active

vibration or noise control systems, medical and

industrial ultrasonics, pumps, and

sonar. If there is a down side to Amorphous Metals it is their current costs. Metglas® is a registered trademark of Allied Metglass Products. All product names and logos contained herein are the trademarks of their respective holders. The fact that an item is listed here does not mean we promotes its use for your application. No endorsement of the vendor or product is made or implied. If you would like to add any information on this topic or request a specific topic to be covered, contact Circuit Cellar provides up to date

information for engineers, www.circuitcellar.com

for more information and additional

articles. |

|